Miter saws are useful when you’re making quick and accurate crosscuts in a workpiece. For optimal performance, you will need to fit nothing but the best miter saw blade to your drop saw.

In this article, we have included a well-laid buyer’s guide to help you in your shopping adventure. We understand how hard sourcing for the best blade can be. Be sure to read on and find out some of the best blades worth investing in.

Table of Contents

5 Best Miter Saw Blades – Reviews

1. Freud D12100X 100 Tooth – Best 12 Inch Miter Saw Blade

When it comes to durability, only a few miter saw blades can match Diablo Freud D12100X. That’s because high-quality carbide material goes into the construction of the blade. With such a material, the blade and its edge have extended integrity for prolonged service.

Specifically, the blade comprises not just any material but Tic Hi-Density carbide. The material wears down at a controlled rate, which means you can always expect your unit to last longer than others. Besides, the blade has Parma-Shield nonstick coating for protection against corrosion, gumming as well as heat.

Not only is the edge durable but tough as well. It can cut through hardwood and plywood with the kind of smoothness that a hot knife slices through butter! You could also cut Aluminum, steel and other metals with the blade though at a cost.

Such metals drastically reduce the edge of the blade overtime. Also, the blade has a 12-inch diameter and 100 teeth. With a speed of 6,000 RPM, the blade does a great cutting job. It operates smoothly and quietly, thanks to the super-thin laser cut kerf and newly designed laser-cut stabilizer vents.

- It has tri-metal brazing for shock-free performance.

- The blade has laser-cut slots to allow its expansion.

- The Parma-Shield nonstick coating protects the blade from corrosion and heat.

- Fast and smooth cuts effortlessly.

- Durable and well design

- Has 100 strong carbide teeth.

- Its teeth might bend during performance.

- The pricing might be quite expensive for some users.

2. Makita A-93681 80 Tooth Micro Polished – Best 10 Inch Miter Saw Blade

If you’re looking for affordability and high performance at the same time, then Makita A-93681 miter saw blade might be the unit you’re searching for. High-quality carbide and steel materials go into constructing the blade. This can only mean that it will stand the test of time!

The blade comprises hardened and fully hand-tensioned steel plate for durable performance. The blade has 80 micro-grain carbide teeth all of which are honed with 600 grits for a spectacular and elegant mirror finish.

The teeth feature the ATAF (Alternative Top and Alternative Face) design which comes in handy when you want to make ultra-thin and precision cuts. The teeth design makes the blade ideal for cutting materials such as plywood, hardwood, and softwood.

Also, with its ultra-thin kerf, the blade delivers smoother cuts that don’t take a toll on the electric motor of the miter saw unit. The kerf design also results in less dust in your workspace. You can also make excellent crosscutting with the blade effortlessly.

And just as you’d expect from a miter saw blade worth mentioning, this one has laser-cut slots which let it expand when heat builds up during a performance. It’s from a reputable manufacturer and you can count on it to perform excellently for a long time.

- Blade makes smooth and thin cuts effortlessly.

- Has laser-cut slots for expansion when heat builds up.

- The teeth are carbide-made for durability and toughness.

- Reasonable Price

- Teeth design for accurate cutting

- Its teeth might become dull overtime.

- Used to cut wood not metals

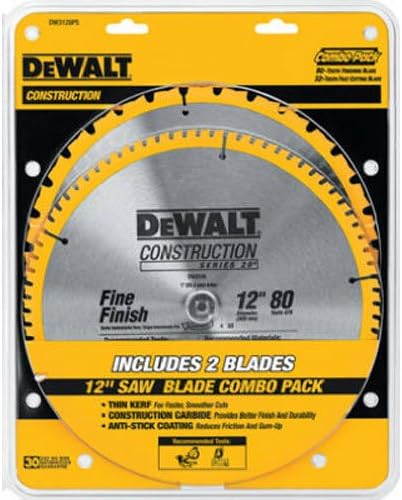

3. Dewalt DW3128P5 12-Inch 80 Tooth

If you opt for this product, you get two Dewalt miter saw blades. One of the blades has 80 teeth while the other has only 32 teeth. Despite their difference in the number of teeth, they are all high-quality and will have extended performance.

High-quality tungsten carbide goes into manufacturing their teeth. Since their material is of top-quality, you can expect your blades to retain their sharpness for a long time. They each have a 12-inch diameter and the brand’s signatory yellow rims.

You will also find their thin kerf design very useful for a smooth and fast cut on materials such as softwood and hardwoods. Also, you can use the blade to smoothly cut chip boards and plywoods. Computer balancing of the steel plate of the blades makes them have reduced vibrations during operations. This is crucial for accuracy and excellent finish.

You can use the 32 teeth blade to make rough cuts instead of fine. And for finer cuts, you will obviously need the 80-tooth blade. Besides, they are within an affordable price range.

- Smooth cut and fast performance.

- The teeth are ultra-sharp for excellent cuts.

- Durability and toughness.

- Comprises 2 blades offer cutting versatility

- Has computer balanced plates that reduce vibration

- Good warranty

- The 32 teeth option is not ideal for fine cuts.

- Materials flimsy not thick

4. IRWIN Tools Classic Series Steel 180 Tooth

The IRWIN 180T (11870) miter saw blade boats of steel alloy (high-carbon steel) as its material of body construction.

With such a high-quality and strong material, it is bound to last longer than you’d expect. It has a diameter of 10 inches, giving it enough cutting edge for your woodworks.

Also, its cutting edge packs 180 strong precision-ground teeth that rip through any wood material effortlessly. Also, it is able to cut through mild steel hassle-free without causing sparks. Due to its high-carbon steel teeth, the blade has the capacity to withstand wear and tear.

It offers a truly hardened plate for longevity and has a 5/8-inch Arbor size. When you look at its kerf design, you will immediately find out how thin it is. This is helpful when you want to make smooth and accurate cuts.

Also, the ultra-thin kerf design makes sure that your motor doesn’t use more than enough power during the performance.

- Can tolerate speeds of up to 5,900 RPM which is impressive.

- Cuts through various materials such as plywood, plastic and mild steel effortlessly.

- Has an impressive 180 teeth for smoother crosscuts.

- Plate and teeth are strong and sturdy due to the high-carbon steel material.

- Extremely affordable

- The kerf is ultra-thin for smooth and fast performance

- It doesn’t have laser-cut slots to permit expansion.

- Blade dull easily

- Use for dry cuts.

5. Hitachi 115436 12” 80T Fine Finish VPR Miter Saw Blade

The Hitachi 115436 is a premium-quality product that comprises high-quality steel as the material of manufacture. Just from its name, you can tell that it has a diameter whose size is 12-inches or 30 centimeters long.

When the blade combines its 80 micro-grain carbide teeth with a speed of 5,500 RPM, you automatically get smoother and fast cuts. Due to the high-quality teeth material, the blade is set to maintain its sharpness for a long time.

The teeth have tri-metal brazing that delivers shock-free cutting performance. This can only mean smooth and fine finishes during your DIY woodwork projects. And to further reduce any vibrations that might arise during a performance, the blade has an excellently balanced plate.

With its laser-cut expansion slots, you can cut materials such as hardwood, softwood or plywood without having to worry about heat distorting your blade. The blade also has an electrophoresis coating that keeps corrosive elements at bay.

- Ideal for cutting OSB(oriented strand board)

- The high-quality Japanese steel guarantees durability and toughness.

- The tungsten carbide tips retain sharpness for a long time.

- The blade is corrosion-resistant due to its electrophoresis coating.

- It has laser-cut expansion slots for excellent expansion when heat builds up.

- The blade might warp when cutting some materials.

- Assembling the blade into a miter saw might take long.

Things To Consider When Selecting The Best Miter Saw Blade

There’s no better way of buying the best miter saw blade other than looking out for a few factors or features. So, what are these factors that you should make sure are present in your blade?

Material

Before buying a specific miter saw blade, you will have to consider the material of its body construction. These blades come in varying materials with common materials being steel, carbide or industrial diamond finish.

Steel-made blades are expensive only that they become dull faster than the ones that feature the other materials. Carbide-tipped blades are equally expensive and they retain their sharpness for a longer period.

Blades with industrial diamond are best for ceramics and masonry works such as tiling. If you’re looking for prolonged performance, you can choose a steel-plated blade with carbide teeth. They cut through various materials excellently and retain their sharpness.

Durability

If you choose a unit whose material of construction is of excellent quality, you will end up with a highly durable miter saw blade.

Therefore, durability is a crucial factor to consider. If your blade has micro-grain carbide teeth, it will retain its sharpness for a longer time, which improves durability further.

The rest of the plate can be hardened steel so your unit can handle heavy-duty performance for long!

Number of Teeth

Miter saw blades come with varying number of teeth with some having 100+ teeth. Teeth come in handy during cuts of materials. For smooth finished cuts, you should settle for a blade with more teeth say, 80 teeth.

Not only should the teeth be 80 in number. That’s not enough. The teeth should be Aluminum-made and have carbide-made tips and ultra-thin kerf design. This will guarantee prolonged sharpness and excellent smooth cut performance.

Also, each tooth should have a size of 1/8 inches for excellently smooth cuts. For rougher cuts, you can always choose a blade with fewer teeth and slightly thicker kerf design.

Size and Thickness

The size and thickness of a miter saw blade plays a crucial role in terms of performance. Thinner circular blades with ultra-thin kerf designs cut a lot faster and smoother and are always sharper. They are ideal for fine cuts of wood materials.

Also, the diameter size of a blade determines the length of the cutting edge. The larger the size of a blade, the longer the cutting edge. Also, the more teeth it can have on the cutting edge! If you intend to cut metallic materials, you should look for thicker circular miter saw blades.

Most circular miter saw blades have a diameter size ranging from 5 to 12 inches. Therefore, it is a great idea to check the recommended diameter size before making a purchase. This will also improve your chances of getting the best miter saw blade for your projects or saw unit.

See also: 10 Inch Vs 12 Inch Miter Saw – Which One Is Right For You?

Material You Want To Cut

Though not a feature, considering the material you intend to cut might help you source the best miter saw blade for the job. Miter saw blades come in varying designs, all of which are suitable for cutting various materials.

If you want to cut wood materials in your masonry projects, you can consider buying Diablo Freud D12100X miter saw blade.

Even if you’re looking to cut some plastic pipe or metal tubes, always there’s miter saw blade for that. It boils down to the material you want to cut through with your miter saw. Once you have figured out what you want to cut, you can then choose a saw blade for the material.

The Blade Tooth Configuration

Teeth configuration is their arrangement. The configuration affects the cutting performance of a blade. You will, therefore, have to choose the right configuration if you want to achieve your desired cut.

Basically, there are 5 configurations. They include the following:

1) Top Flat (FT)

You can find this configuration with the ripping blades. Teeth with this configuration remove chips from the wood fast for rough cuts.

2) Alternate Top Bevel (ATB)

This teeth configuration is present in blades that are suitable for crosscutting operations. Teeth with this arrangement produce smoother cuts when slicing through natural woods and plywood. If you’re looking to crosscut some wood materials, it’s best to settle for this teeth configuration.

3) Combination Teeth

This teeth configuration comprises of a combination of 4 ATB teeth with 1 FT tooth. Blades featuring the configuration are ideal for both ripping and crosscutting operations.

4) Triple Chip Grind (TCG)

If you’re looking to cut some MDF or plastic, a blade with this teeth configuration will be your best friend. Also, you can cut materials such as non-ferrous metal with the blade. The configuration comprises of alternating “raking” tooth and “trapeze” tooth which is slightly higher than the former.

5) High Alternate Top Bevel (Hi-ATB)

Miter saw blades whose teeth feature this configuration are best for extra-fine crosscutting operations. As such, you can use them to cut materials with a melamine surface since melamine is prone to chipping.

The Gullet

In simple term, the gullet is the space between the teeth of a miter saw blade. The size of the gullet determines the outcome of the cut.

Larger gullets in ripping miter saw blades produce larger chips because their designs aim to remove larger portions of the wood material you are cutting for fast but rough performance.

On the contrary, the gullets on a crosscutting circular miter saw blade are smaller for smoother and finer cuts. They produce thinner and smaller chips, which can only mean that they result in very smooth and fine cuts.

So, you will have to choose a blade with larger gullets if you’re looking for a ripping miter saw blade. You will also have to choose a blade with smaller gullets if you want to make smooth and fine cuts during crosscutting operations.

But if you’re looking for a blade that’s suitable for both ripping and crosscutting operations, you can choose a combination blade. Their gullets are designed for the two operations.

Hook Angle

The blade’s hook angle dictates how it cuts materials such as wood. For instance, blades with either low or negative hook angles tend to “climb” the materials they cut. Therefore, they don’t cut aggressively but cut smoothly for finer finishes.

Blades with higher or positive hook angles rip through materials with a lot of aggressiveness. They have a faster feed rate and cut with speed. They are ideal for use in ripping operations. After assessing the kind of cuts you need, you can choose a blade with the appropriate hook angle.

Width of Kerf

The kerf is the slot that a blade makes after a cut. Therefore, the kerf width is a crucial factor to consider if you want to get the best blade. Generally, there are two kerf widths- full-kerfs and thin-kerfs.

Full-kerf blades cut a slot whose size is 1/8 inches. On the other hand, thin-kerf blades cut less than 1/8-inch slots. If your miter saw has a motor of 3 horsepower or more, you should use a full-kerf blade. If the motor power is less than 3hp, a thin-kerf blade will be the best option.

Besides, thin-kerf blades don’t chip off larger chips hence produce smoother and finer cuts. Therefore, they don’t need a lot of motor power to operate.

Laser-Cut Expansion Slot

Blades tend to heat up while in operation. You should make sure that your blade has laser-cut slots that permit expansion. This will reduce the chances of distortion or warping of the blade.

Frequently Asked Questions (FAQs)

1. How Many Teeth Should A Miter Saw Blade Have?

Miter saws come in handy when fitting joints together. You could fit varying circular blades in terms of the number of teeth. For optimal performance and slots with clean edges, you should have a blade with at least 80 tooth. Such blades are best for crosscutting operations.

2. Can I Use A 10-inch blade On A 12-inch Miter Saw?

You can use a 10-inch blade with a 12-inch miter saw provided the Arbor size is the same, but you cannot use a 12-inch blade with a 10-inch miter saw. First, 10-inch miter saws have lower motor power which means you will overburden the unit if you fit a 12-inch blade.

12-inch blades are heavier than their 10-inch counterparts. A miter saw will require more motor power to spin them at a given RPM. Since 12-inch miter saws are powerful enough for their 12-inch blade, fitting a 10-inch blade on them will not slow them down but instead, increase the RPM, which means you will make smoother and finer cuts.

3. Can I Use My Miter Saw To Cut A Metal?

If you choose the correct blade, you can use your miter saw to cut a metallic material. For instance, if you opt for a carbide blade, you can cut an Aluminum with it though the tips of the teeth will wear out a lot faster.

4. What Blade Should I Use To Cut Hardwood Flooring?

Hardwood flooring doesn’t require a substandard blade if you want optimal cuts. As such, you should choose a standard blade with 40 carbide-tipped teeth or more for clean, perfect cuts. Diablo miter saw blades are one of the perfect solutions you can have at hand.

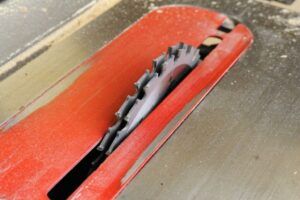

5. Can You Use A Miter Saw Blade On A Table Saw?

You could use your miter saw blade on your table saw provided the kerf is not thinner than the table saw’s splitter. If the splitter is thicker, you might want to replace it so it matches the kerf in thickness since workpieces tend to get stuck on thicker splitters, making it hard to feed them through.

6. Are More Teeth On A Saw Blade Better?

It all depends on the nature of the cut you’d like to make. If you want smoother crosscutting operations, a blade with more teeth will excellently do the job. But for ripping cut operations, you will need to have a blade with fewer teeth since they cut faster.

Conclusion

When looking for the best miter saw blade, you will have to consider a few factors and features. Getting your hands on the best blade depends on the features on our buyer’s guide. While all the blades on the list feature by merit, one of them stand out more.

The Diablo Freud D12100X miter saw blade takes the number one spot because it has more teeth (Tic Hi-Density carbide teeth) for prolonged sharpness. The teeth also cut excellently because the blade spins at 6,000 RPM, meaning you can make excellent crosscuts with the blade. It has an impressive 12-inch diameter for optimal performance.

Also, you can consider the runners up- the Makita A-93681 which has an impressive 80 micro-grain carbide teeth for prolonged sharpness and performance. This is a great blade for the money.

Finally, you will need to assess the nature of the cuts you want to make before deciding to buy a miter saw blade. Also, you will assess the blade’s durability among other features.

Fortunately, we have all the features you need to consider in our buyer’s guide section. Be sure to check them all out so you know what features to keep a closer eye on.